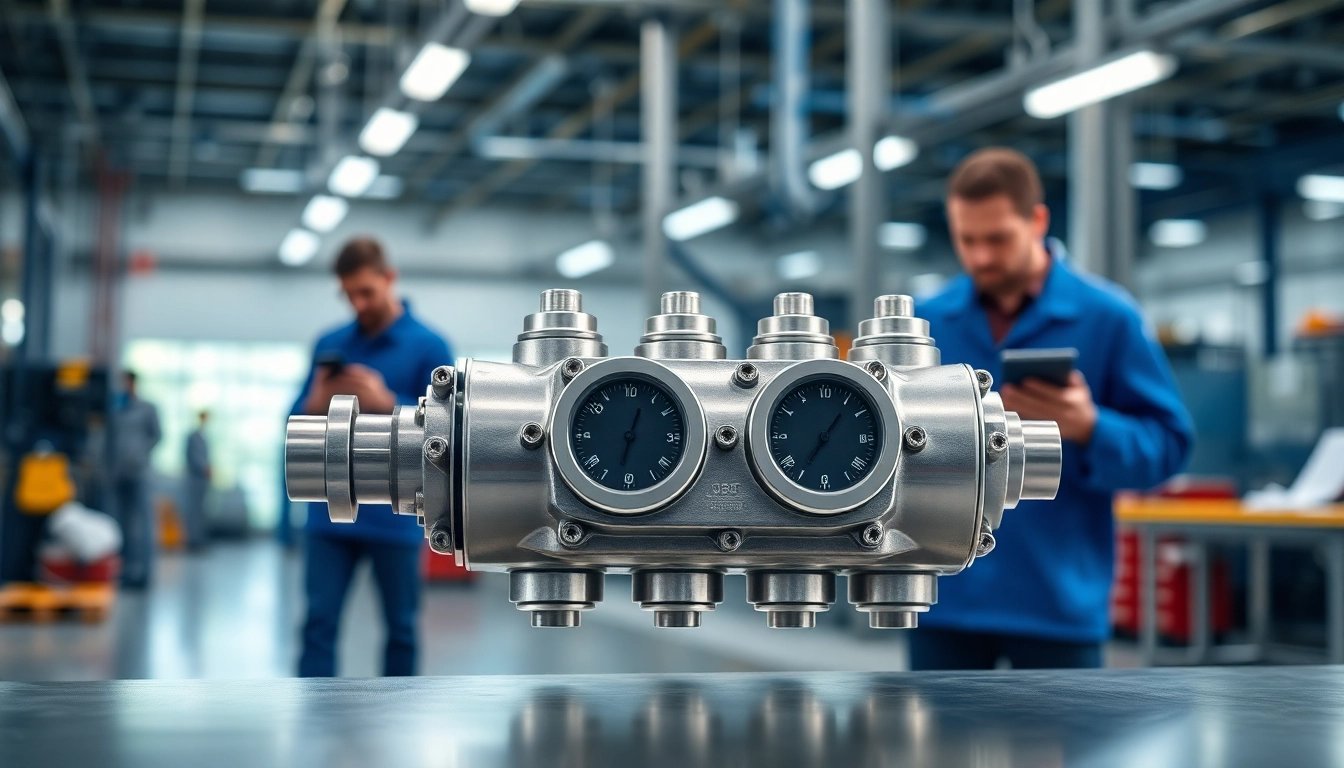

Understanding the HM88 Series Manifold

The HM88 Series Manifold represents a significant advancement in industrial valve technology, specifically designed for precise control of fluid systems across various applications. This manifold system combines efficiency with robust performance, making it an essential component for industries ranging from oil and gas to chemical processing. When exploring options, hm88 offers comprehensive insights into these systems, ensuring operators can optimize their processes effectively.

What is the HM88 Series?

The HM88 Series is a three-valve manifold system that facilitates the management of fluid pressures within piping systems. Its design allows for close-coupled installation of differential pressure transmitters, enabling precise measurements and control. The ability to mount directly onto an orifice flange enhances its applicability in high-performance environments, ensuring that users benefit from streamlined installation and minimized space requirements.

Key Features of HM88 Manifolds

- Compact Design: The three-valve configuration minimizes space without compromising control capabilities.

- Durable Materials: Constructed from high-grade stainless steel, the HM88 is resistant to corrosion and wear.

- Versatile Applications: Suitable for various industries, from petrochemical to HVAC systems.

- Integrated Pressure Control: Provides enhanced safety and efficiency in fluid management.

Applications in Various Industries

The HM88 Series manifolds find extensive use in several sectors, primarily due to their versatility and reliability. Key applications include:

- Oil and Gas: Ensuring accurate pressure readings in extraction and refining processes.

- Chemical Processing: Managing hazardous fluids safely and effectively.

- Water Treatment: Monitoring and controlling water quality in treatment facilities.

- HVAC Systems: Regulating fluid flow and pressure in heating and cooling applications.

Benefits of Using HM88 Series Manifolds

Increased Efficiency and Performance

One of the standout advantages of the HM88 Series is its ability to enhance both efficiency and performance in fluid systems. By enabling accurate control of pressures, the system minimizes the chances of leaks and failures, leading to lower operational costs and increased uptime. Furthermore, the integration of the manifold with transmitters ensures that processes run smoothly, thereby optimizing energy use and prolonging equipment life.

Durability and Reliability in Use

Durability is critical in industrial settings, and the HM88 Series delivers on this front. Constructed from robust materials, these manifolds are designed to withstand extreme pressure and temperatures without sacrificing functionality. Their reliability translates to fewer maintenance requirements and longer service life, ultimately providing significant cost savings for organizations.

Cost-Effectiveness of the HM88

While the initial investment in the HM88 Series may be higher than other options, its long-term benefits justify the cost. Reduced maintenance needs, extended lifespan, and enhanced efficiency contribute to lower overall operational costs. Additionally, the ability to prevent costly downtime due to equipment failure makes the HM88 a smart financial choice for businesses focused on sustainability and profitability.

Installation and Maintenance of HM88 Manifolds

Step-by-Step Installation Guide

Installing the HM88 Series manifold is straightforward, provided that operators follow the detailed guidelines:

- Ensure all tools and materials are ready, including proper gaskets and sealing compounds.

- Prepare the site by cleaning the mounting area to prevent contamination.

- Position the manifold carefully and align it with the orifice flange.

- Secure the manifold using the recommended torque settings to prevent leaks.

- Connect the pressure transmitter and check for proper alignment and function.

Routine Maintenance Practices

Regular maintenance of the HM88 Series is essential to ensure optimal performance. Recommended practices include:

- Visual Inspections: Check for leaks or signs of wear regularly.

- Calibrating Sensors: Ensure all attached sensors are calibrated according to manufacturer specifications.

- Cleaning: Remove any debris or contaminants from the system to maintain flow efficiency.

Common Issues and Troubleshooting Tips

Even the best systems can encounter challenges. Common issues associated with the HM88 Series and their respective solutions include:

- Leakage: Check all connections and tighten as necessary; inspect seals for damage.

- Inaccurate Pressure Readings: Verify sensor calibration and consider replacing faulty components.

- Blockages: Conduct a thorough cleaning of the manifold and connected piping if flow decreases.

Real-World Case Studies of HM88 Applications

Case Study: Oil and Gas Sector Implementation

In a recent project within the oil and gas industry, a leading company implemented the HM88 Series to manage fluid pressures in a high-pressure extraction process. The result was a 30% reduction in leaks compared to their previous system, significantly enhancing safety and efficiency.

Case Study: Chemical Processing Success

Another case study in a chemical processing facility highlighted the manifold’s capabilities when handling corrosive liquids. The HM88’s durable construction and precise control features resulted in fewer maintenance interventions, allowing staff to focus on core operations rather than equipment issues.

Lessons Learned from HM88 Usage

The experiences from these implementations underscore the importance of selecting the right equipment for specific applications. Organizations that invested in the HM88 Series not only reaped financial benefits but also improved operational safety and environmental compliance.

Future Trends and Innovations in Manifold Technology

Emerging Technologies in Fluid Mechanics

As fluid dynamics technology evolves, so too does the landscape of manifold systems. Innovations such as smart technology integration and advanced materials are paving the way for even more efficient solutions.

Predictions for Manifold Efficiency Enhancements

Industry experts predict that future iterations of systems like the HM88 will feature enhanced automation capabilities, allowing for real-time monitoring and adjustments based on fluid dynamics. This will lead to even higher efficiency ratings and reduced operational risks.

Why HM88 Stands Out in 2025 and Beyond

In 2025 and beyond, the HM88 Series is expected to be at the forefront of manifold technology, combining ease of use with advanced performance metrics. Its continued focus on durability, efficiency, and cost-effectiveness will solidify its position as a go-to solution for industries that demand reliability and precision.